Energy-Saving Pneumatic Industrial Diaphragm Pump Low Risk Of Leakage

Pneumatic Diaphragm Pump Introduction

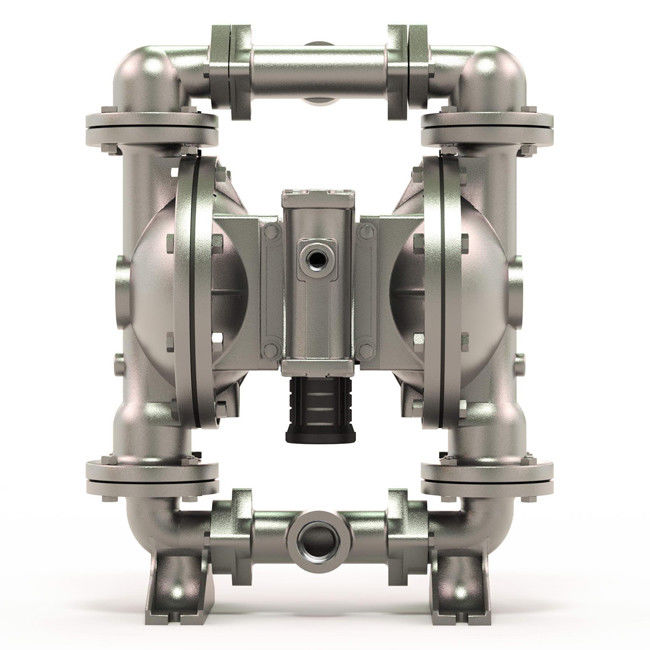

A pneumatic diaphragm pump is a type of positive displacement pump that uses compressed air to move fluids. It is also known as an air-operated diaphragm pump (AOD pump). The pump is designed with two flexible diaphragms that reciprocate back and forth, creating a vacuum effect that draws fluid into the pump chamber and then forces it out under pressure.

Pneumatic diaphragm pumps are widely used in various industries, such as chemical, pharmaceutical, food and beverage, mining, and wastewater treatment, among others. They are versatile and can handle a wide range of fluids, including corrosive, abrasive, and viscous liquids, as well as slurries and solids-laden fluids.

One of the advantages of pneumatic diaphragm pumps is their ability to handle varying flow rates and pressures, as well as run dry without causing damage to the pump. They are also relatively easy to maintain and operate, with no electrical components or seals to worry about. Additionally, they are considered to be a safer option compared to other types of pumps, as they are designed with a leak-free mechanism that prevents fluid from escaping into the environment.

Pneumatic Diaphragm Pump Main Features

- No need for irrigation and diversion, it can work submerged in the medium, the suction lift is up to 5m, the lift is up to 50m, and the outlet pressure is ≥6bar.

- The flow is spacious and the passing performance is good, the maximum particle diameter allowed to pass is 10mm. When pumping mud and impurities, there is little wear on the pump.

- Head and flow can be adjusted steplessly through the opening of the air valve (the air pressure can be adjusted between 1-7 bar).

- The pump has no rotating parts and no shaft seal. The diaphragm completely separates the pumped medium from the moving parts of the pump and the workpiece medium, and the transported medium will not leak out.

- Simple structure, less wearing parts, the pump is simple in structure, easy to install and maintain.

- Can transport viscous liquid (viscosity below 10,000 centipoise).

- The pump does not need to be lubricated with oil, even if it is idling. It has no effect on the pump, which is the biggest feature of the pump.

- Easy to use, reliable work, just open and close the gas valve to start and stop.

Pneumatic Diaphragm Pump Advantages

-

Versatility: Pneumatic diaphragm pumps can handle a wide range of fluids, including abrasive, viscous, and corrosive liquids, as well as slurries and fluids containing solids.

-

Self-priming: Pneumatic diaphragm pumps are self-priming, which means they can start pumping without the need for manual priming.

-

Dry running: Pneumatic diaphragm pumps can run dry without causing damage to the pump.

-

Solids handling: Pneumatic diaphragm pumps can handle fluids with high solids content, making them suitable for applications such as wastewater treatment.

-

Easy maintenance: Pneumatic diaphragm pumps have a simple design and few moving parts, making them easy to maintain and repair.

-

Safe operation: Pneumatic diaphragm pumps are safe to operate because they are powered by compressed air, which eliminates the risk of electric shock.

-

Energy efficient: Pneumatic diaphragm pumps are energy efficient because they use compressed air as the power source, which is often readily available in industrial settings.

Pneumatic Diaphragm Pump Scope Of Application

- Low, medium and high viscosity liquids: such as resins, paints, paints, glues, cosmetics, jams, honey, etc.

- Corrosive liquids: such as acids, alkalis, brines, chlorides, chlorine, fluorides, etc.

- Liquids with high dust and solid particle content: such as sludge, sewage, sediment, lime slurry, ore slurry, etc.

- High temperature and low temperature liquids: such as hot oil, boiling water, liquid nitrogen, liquid oxygen, etc.

- Flammable and explosive liquids: such as gasoline, kerosene, solvents, alkyl, ketone liquids, etc.

- The liquid contains bubbles or gas: such as mud, foam liquid, chemical liquid with high bubble content, etc.

- Occasions where the viscosity of the liquid changes greatly: such as liquids containing solid particles, high-temperature liquids, etc.

- Light liquids: such as beverages, alcohol, cosmetics, etc.

Pneumatic Diaphragm Pump Performance Parameter Table

| Product Name |

Energy-Saving Industrial Pneumatic Diaphragm Pump Low Risk Of Leakage For Various Liquids |

| Max flowrate |

Up to 1000 L/min |

| Max pressure |

Up to 8.6 MPa |

| Head |

Customizable |

| Solids handling |

Up to 10 mm |

| Air inlet size |

1/4 inch NPT |

| Fluid inlet/outlet size |

1 inch NPT |

| Max temperature |

Up to 120°C |

| Max viscosity |

Up to 50000 cps |

| Wetted materials |

Aluminum, Stainless Steel, PTFE, Santoprene |

| Air supply pressure |

1.4 - 8.6 bar |

| Air consumption |

0.4 - 1.2 m³/min |

| Noise level |

70 - 75 dB(A) |

| Features |

Self-priming, dry running, no seals, low pulsation |

| Applications |

Chemical transfer, paint circulation, ink transfer, wastewater treatment, food processing

|

Huatao Supply The Spare Parts For All Kinds of Pump

Huatao Pumps Application

Huatao Pumps Package, Shipment, Workshop

Exhibition And Customer Visting

Please ask for pump details and price by chris@huataogroup.com, Whatsapp: 0086 137 0329 5214.

For any questions will reply within 24 hours.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!