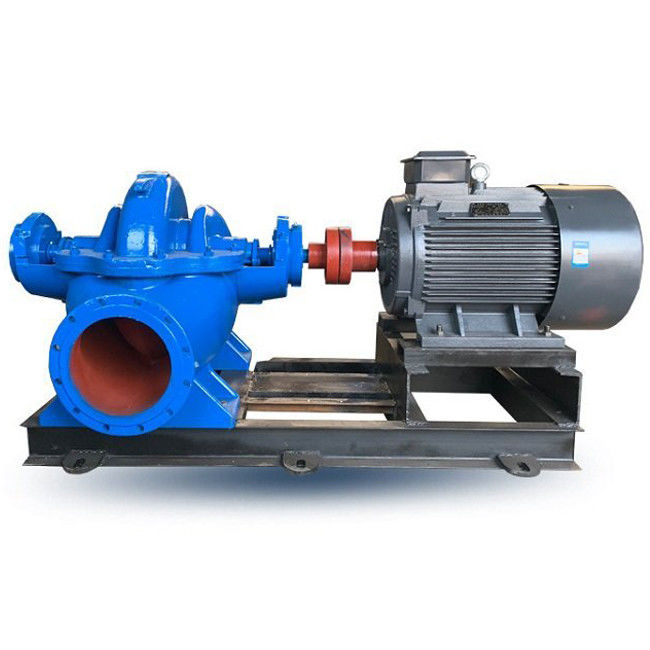

Wear Resistance Centrifugal Open Impeller Low Pulse Pulp Pump For Paper Pulp

Low Pulse Pulp Pump Details

Open-impeller pulp pumps are based on new technology, the pump is successfully designed based on long-term technology accumulation and on the experience of domestic and overseas advanced technology.

The pump has a strong capacity to transport fiber, mud, paper pulp below 5% consistency, and other liquid with below 30% solid content. It can be used in those operating environments in paper making, metallurgy, salt collecting, drainage and power plant, etc.

The casing is end suction and radial discharge design. Its discharge centerline and shaft are in the same vertical plane. The casing is directly fixed on the base plate.

The front wear plate and back wear plate be designed for a stripped-down structure. We can replace the worn part when the inter-spacer becomes large.

Operation Conditions

> Pulp Consistency: ≤ 6%.

> Solid Content: ≤ 30%.

> Max. Viscosity: 300cP, Normal temperature (24ºC)

> Working Temperature Range: -20ºC ~ 120ºC

Low Pulse Pulp Pump Structure feature

Its inlet and outlet are under and perpendicular to the axis line, and horizontal direction. The pump shell parts itself from the middle, so there is no need to remove the in and out of the water pipes and motors. Looking from the coupling to the direction of the pump, it’s turns in the clockwise direction ( ant- clockwise is available).

Low Pulse Pulp Pump Advantage

1. Port width, no jam

2. Easy to disassemble, easy to maintain

3. Spare parts versatility, bearing seat is interchangeable with other types

4. Safe, reliable range of application

Low Pulse Pulp Pump Application

1. Contain liquid of wood, grass, reeds

2. Liquid containing highly corrosive medium

3. Mud containing large granular impurities

4. Long fiber pulp

5. Liquid of inflatable or high air content, etc

| • Paper mills |

• Paper pulp |

• Mining water |

• Waste pulp |

| • Paper stock |

• Chemical slurry |

• Sugar refining |

• Cooling water |

| • Papermaking |

• Chemical industry |

• Food industry |

• Circulation water |

| • Water supply |

• Wastewater treatment |

• Raw water |

• Sugar syrup |

| • Molasses |

• Drinking water |

• Filtrate |

• Other industries |

After telling us your needs, a detailed quotation will be sent to you, which includes a CAD layout drawing and all machinery lists with specifications. Popular pulp-making equipment includes a double-disc pulp refiner, double screw pulp squeezer, fiber separator, drum screen, high-speed pulp washer, high-consistency sand remover, low-consistency impurity remover, reject separator, flotation deinking machine, vibration screen, cylinder pulp thickener, pressure screen, pulp pump, pulp consistency controller, high consistency bleaching system, disc heat dispersing system, etc.

Huatao Supply The Spare Parts For All Kinds of Pump

Huatao Pumps Application

Huatao Pumps Package, Shipment, Workshop

Exhibition And Customer Visting

Please ask for pump details and price by chris@huataogroup.com, Whatsapp: 0086 137 0329 5214.

For any questions will reply within 24 hours.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!